Single-Bend vs Continuous-Flex Wires Explained

-

When selecting Flexible wires for control cables in UAE, understanding how the cable will move during its service life is just as important as electrical specifications. One of the most common points of confusion among engineers, installers, and procurement teams is the difference between single-bend and continuous-flex control wires. Choosing the wrong type can lead to premature cable failure, unplanned downtime, and increased maintenance costs. This article explains the key differences between these two wire types, their applications, and how to select the right option for long-term reliability.

Understanding Cable Flexing in Control Applications

Why Cable Movement Matters

Control cables are often routed through panels, machines, and equipment where movement may occur during installation or operation. This movement creates mechanical stress on the conductor and insulation. If the wire is not designed for the specific type of motion, internal damage can occur even when the cable appears intact externally.

Types of Cable Motion

Cable motion typically falls into two categories:

-

Occasional or one-time bending

-

Repeated or continuous bending

This distinction forms the basis for choosing between single-bend and continuous-flex control wires.

What Are Single-Bend Control Wires?

Definition

Single-bend control wires are designed to withstand one-time or infrequent bending, usually during installation. Once positioned, the wire remains static throughout its operational life.

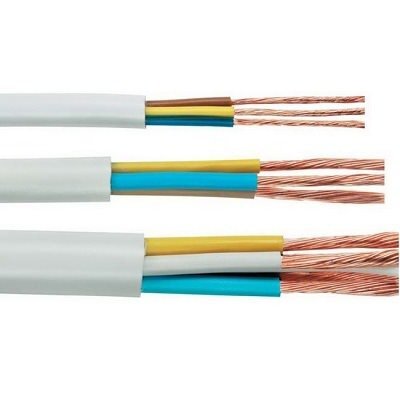

Construction Characteristics

-

Moderately stranded conductors

-

Insulation designed for fixed installations

-

Limited tolerance for repeated mechanical stress

Typical Applications

-

Control panels and switchboards

-

Fixed industrial machinery

-

Building automation systems

-

Static wiring inside enclosures

Advantages

-

Lower initial cost

-

Suitable for stationary environments

-

Easy to terminate and install

Limitations

-

Not designed for ongoing movement

-

Repeated bending can cause conductor fatigue

-

Reduced lifespan if used in dynamic systems

What Are Continuous-Flex Control Wires?

Definition

Continuous-flex control wires are engineered to handle constant or repetitive bending, twisting, or movement throughout their service life. They are commonly used in dynamic industrial environments.

Construction Characteristics

-

Fine-stranded conductors for flexibility

-

Reinforced insulation for mechanical endurance

-

Designed for millions of bending cycles

Typical Applications

-

Automation systems

-

Moving machinery parts

-

Cable carriers and drag chains

-

Robotic arms and production lines

Advantages

-

Exceptional durability under motion

-

Reduced risk of conductor breakage

-

Longer service life in dynamic applications

Limitations

-

Higher upfront cost

-

Over-engineered for static installations

-

Requires careful selection based on motion type

Key Differences Between Single-Bend and Continuous-Flex Wires

Mechanical Endurance

Single-bend wires tolerate limited movement, while continuous-flex wires are built to withstand constant motion without degradation.

Conductor Design

Continuous-flex cables use finer stranding to distribute mechanical stress evenly, whereas single-bend cables use coarser strands.

Installation Environment

Single-bend wires are ideal for enclosed, stationary setups. Continuous-flex wires perform best in open or moving systems.

Service Life

Using a single-bend wire in a dynamic application drastically shortens its lifespan. Continuous-flex wires maintain integrity over extended cycles.

How to Choose the Right Control Wire

Evaluate Movement Frequency

Ask whether the wire will move once, occasionally, or continuously. This is the most critical selection factor.

Consider Bend Radius

Continuous-flex wires typically support tighter bend radii, reducing stress during movement.

Assess Mechanical Stress

Vibration, acceleration, and torsion all increase wear. Continuous-flex designs are better suited for such conditions.

Balance Cost and Performance

While continuous-flex wires cost more initially, they prevent costly failures and downtime in moving systems.

Common Mistakes in Cable Selection

Using Single-Bend Wires in Dynamic Systems

This leads to conductor breakage, insulation cracks, and unpredictable failures.

Over-Specifying for Static Installations

Using continuous-flex wires where no movement exists can unnecessarily increase project costs.

Ignoring Future Equipment Changes

Systems that may later incorporate motion should be wired with flexibility in mind from the start.

Impact of UAE Operating Conditions

Temperature Considerations

High ambient temperatures can accelerate insulation aging. Continuous-flex cables are often better equipped to handle combined thermal and mechanical stress.

Industrial Expansion

As automation grows in the UAE, demand for motion-capable control wiring continues to rise.

Maintenance Expectations

Facilities prioritize reliability and minimal downtime, making correct wire selection essential.

Long-Term Benefits of Correct Wire Selection

-

Reduced maintenance and replacement costs

-

Improved system reliability

-

Safer operating environments

-

Better return on investment

Choosing the correct cable type at the design stage prevents avoidable failures and extends system life.

Conclusion

Understanding the difference between single-bend and continuous-flex control wires is essential for building reliable electrical systems. Single-bend wires work well for fixed installations, while continuous-flex wires are critical for applications involving repeated movement. Selecting the right option ensures durability, safety, and cost efficiency. For dependable solutions and expert guidance, Levit Electric offers high-quality Flexible wires for control cables in UAE, supporting a wide range of industrial and control panel applications.

-